Some of the best graphite in the world?

This morning our 2021 Wise-Owl Pick of the Year, Evolution Energy Minerals (ASX:EV1) made further progress with its commercial verification program to evaluate the suitability of its graphite fines product for battery anode materials.

EV1 confirmed that thermal purification achieved an industry-leading purity level of 99.9995% carbon (C).

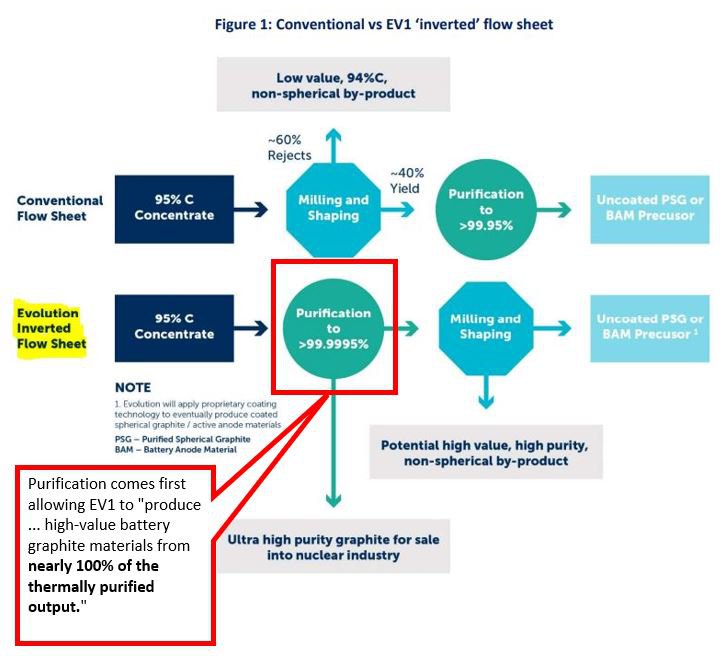

What we’re really interested in from today’s EV1 announcement is the “inversion” of the traditional battery anode process flow sheet:

Importantly, this flow sheet results in a product that exceeds the required purity level for battery grade spherical graphite, while also using an environmentally friendly thermal purification processing methodology.

This compares to the conventional approach which is currently responsible for producing 100% of the world’s battery grade graphite.

The key difference between the two is that the conventional process uses highly toxic chemicals such as hydrofluoric (HF) acid — existing anode manufacturers use between 400-600kg of HF acid for every tonne of graphite feedstock.

Thermal purification, on the other hand, is completely sustainable using no toxic chemicals. This fits in with EV1’s strategy of producing net zero carbon graphite.

We think this is a step in the right direction towards positioning EV1 as the world’s leading producer of the most green and sustainable battery anode materials.

The thermal purification process also has cost advantages. EV1 explains that the cost of the conventional process is ~US$700 per tonne as compared to the thermal purification process which EV1 expects to cost ~US$500 per tonne.

EV1 is making strong progress towards qualifying its graphite fines product as suitable for use in both high performance batteries and in the nuclear industry — where graphite products can fetch as high as US$30,000 per tonne.

We covered this test work in our last EV1 note which you can read here: EV1’s Graphite Meets Purity Standards – Good for Batteries and Nuclear Energy

What’s next for the ongoing test work:

EV1 has confirmed that downstream processing and battery anode testwork is ongoing. The company expects to release the results of testwork on the production of coated spherical graphite in the coming weeks.

Subject to the results of that testwork, EV1 intends to undertake a feasibility study on the production of coated battery anode materials and other advanced battery products.

This, we hope, will lead to improved overall project economics for EV1 as it moves towards making a final investment decision to develop its graphite project in Tanzania.