SS1 - Phased metallurgical testwork underway

Our silver-gold Investment Sun Silver (ASX: SS1) is about to start a phased metwork testing program for its project in Nevada, USA.

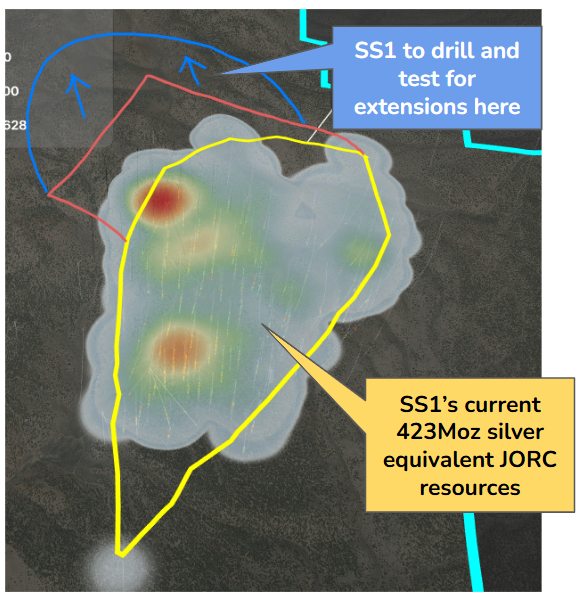

SS1’s project is already the biggest pre-production silver asset on the ASX with a 480M ounces silver equivalent JORC resource.

(2.16M ounces of gold, 296.5M ounces of silver)

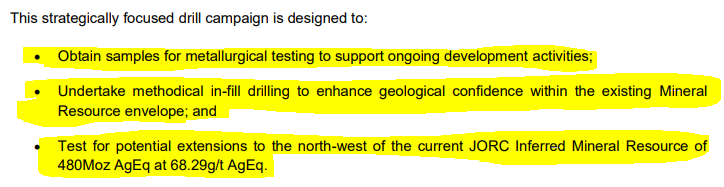

A few weeks ago SS1 kicked off its 2025 drill program which had three key objectives:

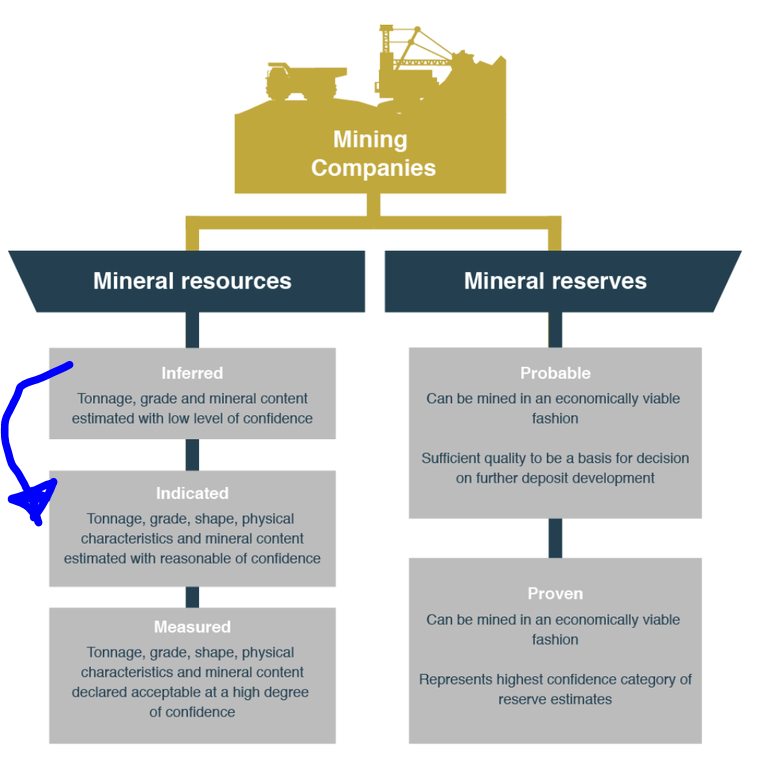

- In-fill drilling to increase the resource confidence category (from inferred into indicated).

- Extensional drilling to increase the size of the resource (targeting extensions to the north-west).

The third objective was to get some drill core that can be used to run metallurgical testing.

(Source)

Today’s announcement gave a good summary of where SS1 is today and what needs to be done to improve on the previous metwork done on the project.

The only testwork done on the project was back in 2002, 2004 and 2006.

The work done in 2004 and 2006 showed that cyanide leach tests returned recovery rates of up to ~97.5% silver and 95.8% gold.

These are seriously strong recoveries already, BUT the data is over 20 years old.

SS1 will be able to run test programs that mimic projects with similar geology - basically, SS1 gets to benefit from the 20+ years of trial and error from operators who have made money year in year out mining their projects in Nevada, USA.

Today’s announcement specifically mentions five different methods SS1 will be testing over and above all the work the previous project owners did:

- Using higher cyanide dosages - This is a very well understood method in Nevada, USA.

- Extended cyanide bottle roll tests - This wasn’t done by the previous companies who did testwork on the deposit.

- Intermittent bottle roll (IBR) and column leach testing - This is to see if SS1’s project is amenable to heap leach mining methods. Again these are very well understood processing methods in Nevada, USA.

- Flotation optimisation studies - No flotation studies were done by the previous operators.

- Mineralogical and diagnostic leach studies - This is where SS1 will be looking to understand the geology a lot better and work out the right amounts of everything above to optimise recoveries.

We are hoping to see SS1 announce a set of testwork that is similar to the ones being used by other operators in Nevada, USA.

IF SS1 can show that it’s deposit can be mined and processed using conventional, well understood processing methods then it would answer a big technical question that any corporates or strategic investors have over the project.

At a very high level, we think that positive metwork results could unlock deeper pocketed investors/corporates who may be sitting on the sidelines waiting for the project to be de-risked from a processing perspective.

SS1 did say in today’s announcement that “Metallurgical test work will be executed in multiple phases” so we should see multiple sets of announcements over the coming months.

Why is metwork important?

At a very high level, Metwork results are the technical inputs a mining company uses to work out how much of its deposit can be economically extracted.

The studies happen continuously over years as the project is being developed and an optimal flowsheet is usually locked in just before the company starts going out to tender for construction of it’s project.

First companies will take samples from the deposit and run tests in labs. Then once the most optimal flow sheet is locked in the company can scale it up and build the same set of processing steps in one big plant on site:

(Left = lab scale) (Right = project scale)

High recovery rates, using conventional well understood processing methods is what we want to see when a company runs metwork testing.

Conventional methods mean the technical risk of the processing method working is low and high recovery rates mean more of the orebody can be turned into payable metals…

What’s next for SS1?

Drilling results 🔄

We will be watching out for announcements from drill results to the north-west of SS1’s project.

Any big extensional hits here could add SHALLOW high grade ounces to the current JORC resource.

We also want to see SS1 confirm its understanding of the deposit with its in-fill drill programs.

The in-fill results will be important for SS1 to be able to upgrade some portion of its inferred resource into the higher confidence resource estimate categories (indicated/measured)

Metallurgical testing results 🔄

As mentioned in today’s QuickTake we want to see improved recovery rates from the testwork SS1 will be doing.